Isolators in microbiological QC rooms play a key role in ensuring a completely sterile testing environment. By completely isolating the operator from the test sample, isolators help improve accuracy, safety and meet the strict requirements of GMP Annex 1.

- 1. What is an Isolator? Its Role in a Microbiological QC Laboratory

- 2. Key Benefits of Using Isolators in Microbiology QC Labs

- 3. Common Applications of Isolators in Microbiological QC

- 4. When Should You Use an Isolator Instead of a Biosafety Cabinet?

- 5. Frequently Asked Questions

- 6. Need a GMP-Compliant Isolator Solution for Your Microbiology QC Lab?

1. What is an Isolator? Its Role in a Microbiological QC Laboratory

What is an Isolator?

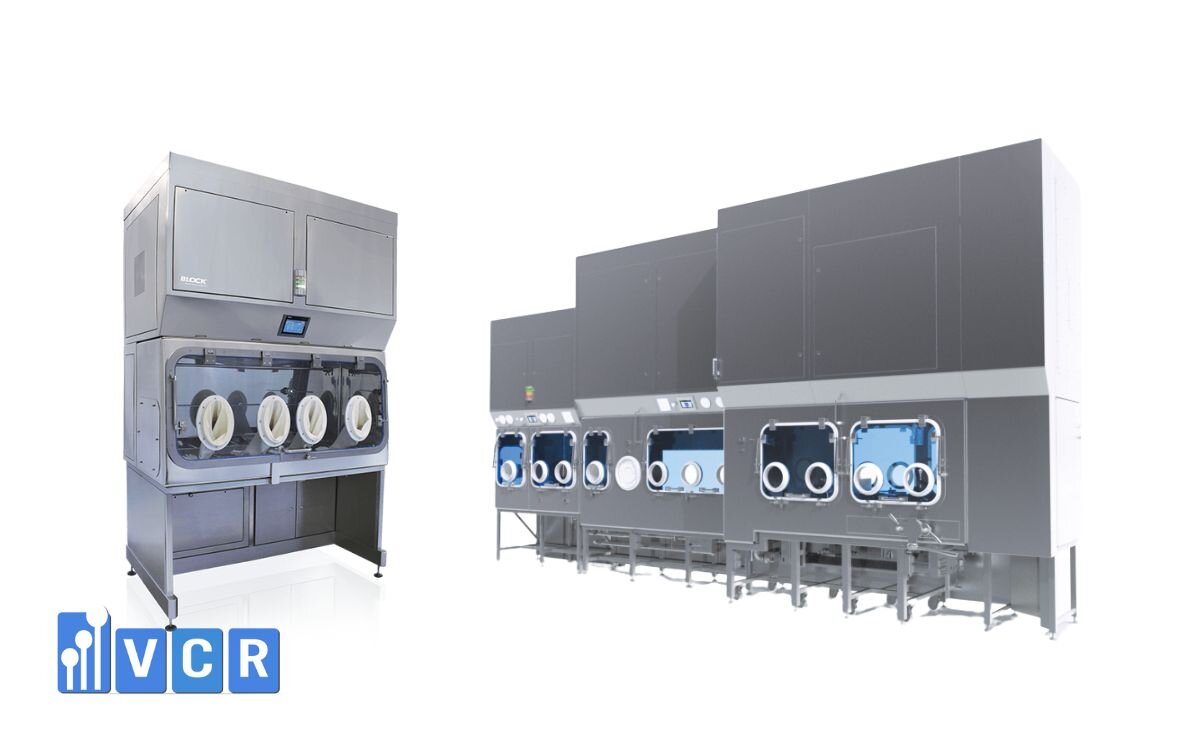

An isolator, also known as a microbiological isolator, is a sealed enclosure designed to protect the working environment from external microbial contamination, while also isolating the operator from direct contact with test samples. Inside the isolator, air is filtered through HEPA or ULPA systems, and positive or negative pressure is precisely maintained to ensure an absolutely sterile environment.

In microbiological quality control (QC) labs within pharmaceutical manufacturing, isolators are almost essential, especially for testing activities that require absolute sterility, such as sterility testing, injectable product testing, or biologics.

Why Are Isolators Preferred in QC Microbiology?

According to the latest GMP Annex 1, sterility testing must take place in a Grade A environment, completely isolated from operators. Isolators are the ideal solution to:

- Ensure complete physical separation between operator and product.

- Reduce reliance on room classification - only a Grade C room is required, instead of Grade B as needed for biosafety cabinets.

- Increase safety and traceability - operations within the isolator can be recorded and remotely monitored for future review.

- Lower long-term operating costs - due to reduced HVAC requirements.

For these reasons, isolators are increasingly becoming the standard equipment in QC microbiology labs of facilities producing injectables, vaccines, or sterile biological products.

2. Key Benefits of Using Isolators in Microbiology QC Labs

2.1. Enhanced Protection for Samples and Operators

Isolators operate as sealed chambers, using glove ports for manipulation. This design ensures that:

- External air cannot enter the working chamber.

- Cross-contamination risk is virtually eliminated, even when handling high-risk microbial strains.

- The operator has no direct contact with the sample, ensuring absolute safety during critical tests.

2.2. Absolute Sterile Conditions

One of the standout advantages of isolators is their ability to maintain an independent Grade A environment, unaffected by the surrounding cleanroom level.

- Isolators maintain positive or negative pressure with continuous HEPA/ULPA filtration, removing particles and microorganisms.

- These are critical conditions for sterility testing, ensuring accurate and reliable results.

2.3. Minimized Human Error

Performing procedures in a controlled, enclosed space standardizes handling and:

- Reduces operator variability - a common cause of test inconsistency.

- Many isolator models feature integrated cameras, monitoring screens, and data logging systems to:

- Enable real-time monitoring,

- Allow post-operation review,

- Support investigations in case of deviations.

2.4. Long-term Cost Efficiency

While the initial investment in isolators is higher than biosafety cabinets, they offer substantial long-term savings:

- No need to construct high-grade cleanrooms (Grade B or higher) - a Grade C or D room suffices.

- Lower HVAC costs (cooling, filtration, pressure control) for the entire QC area.

- Space optimization - isolators can be installed in smaller rooms, reducing the area needing cleanroom control.

2.5. Easier GMP Compliance and Audit Readiness

Isolators are specifically designed to meet GMP Annex 1 requirements, which emphasize:

- Physical separation between product and personnel,

- Minimizing direct interaction with high-grade cleanroom air.

This enables:

- Easier audit compliance with regulatory bodies such as FDA and EMA,

- Increased confidence in test integrity,

- Stronger positioning in international drug registration dossiers.

See more: Latest price list of Isolator used in food factory

3. Common Applications of Isolators in Microbiological QC

Isolators are not just advanced cleanroom equipment; they are critical workstations for safe microbiological testing. Here are the most common applications in pharmaceutical, biologics, and vaccine QC labs:

3.1. Sterility Testing

This is the primary application of isolators and a major reason for their mandatory adoption in many facilities:

- Ensures a completely sterile testing environment - required for injectable drugs, biologics, eye drops, etc.

- Fully isolates the operator from the test sample, eliminating contamination risks from breath, sweat, or clothing.

3.2. Microbial Limit Testing (TAMC/TYMC)

In procedures measuring total microbial counts:

- Isolators provide highly controlled conditions for accurate quantification of microbial load in raw materials, intermediates, or finished products.

- They prevent environmental interference, ensuring representative and trustworthy results.

3.3. Isolation and Identification of Contaminating Microorganisms

When microbial contamination is detected in production or testing:

- Isolators provide an ideal environment for isolating and identifying contaminant strains.

- Their tight sterility control ensures more accurate isolation and avoids interference from ambient flora.

3.4. Handling Pathogenic Microorganisms

For dangerous or high-virulence strains:

- The isolator acts as a biological safety containment unit, protecting both the sample and the operator.

- Certain isolator models maintain negative pressure and integrate exhaust filtration systems, making them suitable for vaccine research or handling of hazardous pathogens.

4. When Should You Use an Isolator Instead of a Biosafety Cabinet?

In many microbiological QC labs, a common question is: Should we use an isolator or a biosafety cabinet (BSC)? The choice depends on the required protection level, the nature of the test samples, and GMP compliance needs.

The comparison table below helps identify when an isolator should be prioritized:

|

Criteria |

Isolator |

Biosafety Cabinet (BSC) |

|

Protection level |

Absolute (Closed system) |

Partial (Open front) |

|

Sterility control |

Very high - Grade A environment |

Moderate - Affected by surroundings |

|

Suitable for sterility testing |

Yes |

Not sufficient |

|

GMP Annex 1 compliance |

Fully compliant |

Not fully compliant with the latest revision |

|

Initial investment |

Higher |

Lower |

When to Choose an Isolator:

- When conducting sterility testing in accordance with EU-GMP or FDA.

- When complete isolation between operator and product is required.

- When the QC lab aims to reduce the cleanroom classification of surrounding areas to save operational costs.

- When handling hazardous microorganisms or requiring video/data traceability of operator actions.

See more: How to clean isolator to ensure sterile safety

5. Frequently Asked Questions

Is an isolator mandatory in pharmaceutical QC labs?

Not absolutely mandatory. However, isolators are considered the most viable option when performing sterility testing according to the latest GMP Annex 1. Regulatory audits by EMA, FDA, or WHO often favor isolator-based setups, improving compliance scores and reducing the risk of batch rejection due to insufficient testing conditions.

How often should an isolator be maintained and calibrated?

The maintenance and calibration schedule for an isolator depends on usage frequency, sample load, and internal SOPs. Standard GMP practices suggest:

- Calibration: Every 6 to 12 months.

- Routine maintenance: Quarterly (e.g., HEPA filter checks, pressure verification, leak testing).

- Comprehensive service: Annually or whenever performance deviations are suspected.

Can isolators be used in QC labs for cosmetics or food industries?

Yes. While isolators are common in pharmaceuticals, they are also suitable for cosmetics and food microbiology labs, especially when:

- Testing requires absolute sterility (e.g., preservative-free products).

- Hazardous microbial strains are involved.

- Cross-contamination must be minimized during high-value product testing.

6. Need a GMP-Compliant Isolator Solution for Your Microbiology QC Lab?

An isolator is more than just a piece of equipment - it’s a critical safeguard for your microbiological testing processes. As GMP Annex 1 becomes increasingly stringent, investing in a high-quality isolator helps you:

- Meet international sterility testing standards with confidence.

- Avoid audit failures during inspections by the FDA, EMA, or WHO.

- Optimize cleanroom operating costs by allowing lower-grade surrounding environments.

At VCR, we offer:

- Dry and vapor-phase (H2O2) isolators, with customizable integration options.

- Consulting services for QC room layout, pressure differential planning, and device selection aligned with testing goals.

- Full support for IQ/OQ/PQ qualification, staff training, and regular maintenance.

Contact the VCR engineering team today to receive detailed technical specifications, a customized quotation, or an onsite consultation.

Hotline: 090.123.9008

Email: [email protected]

Website: https://isolator.vn/

Diep VCR