Products

FAST DELIVERY - 24H

inner city Hanoi, HCM

SERVICE 24/7

Professional and dedicated consulting team

LIFETIME SUPPORT

Lifecycle product support

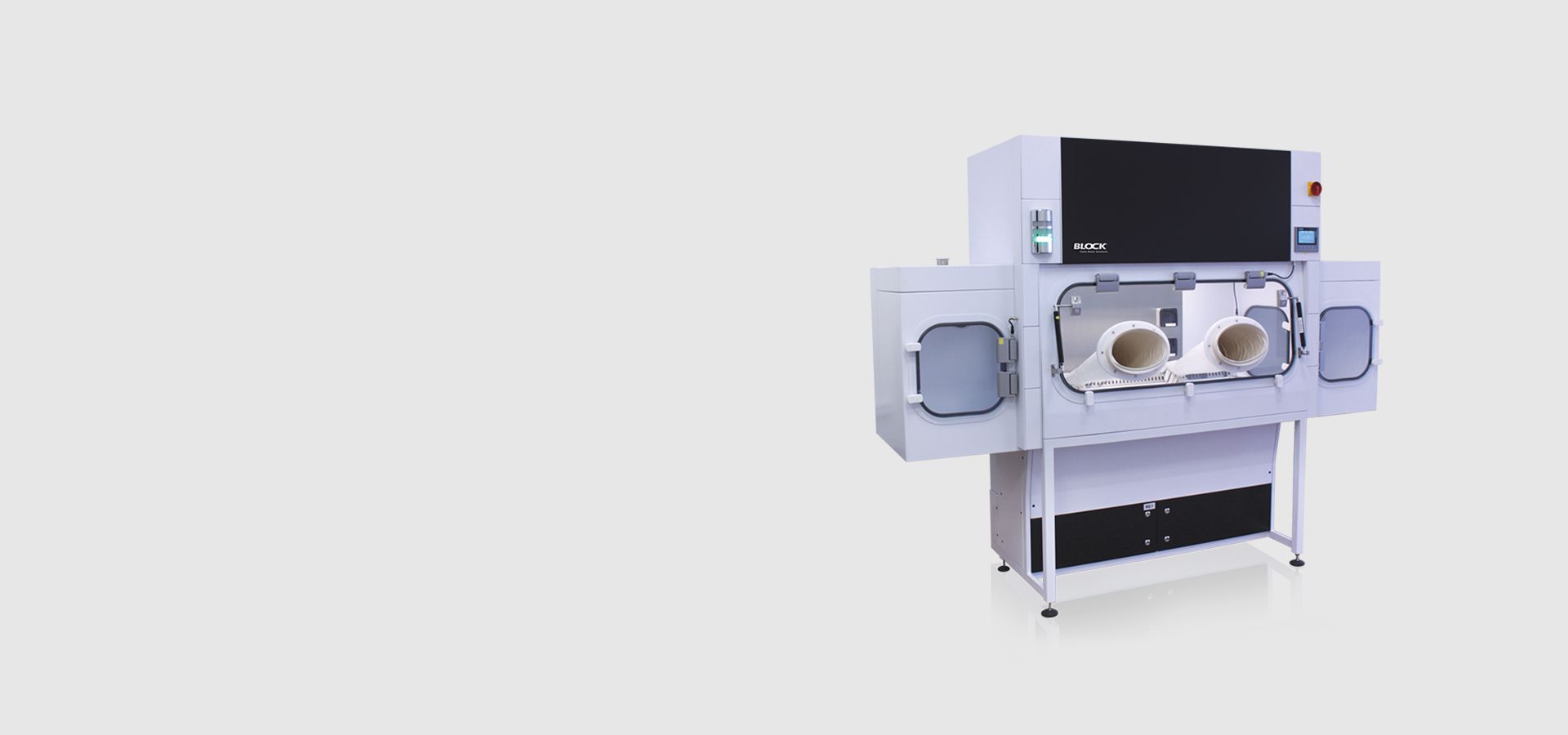

Features Of ISOLATOR VCR

Compliance with Standards

Meeting the strictest standards for hazardous operations

Custom Design

Design tailored to specific customer requirements

Leading Technology

Utilizing cutting-edge technology to create the best equipment

High Quality

Products are finished with excellent quality.

Knowledge About Isolator

FAQs

When are Isolators used?

Isolators are commonly used in applications requiring high levels of protection against external factors or contaminants such as pharmaceuticals, food, biology, laboratories, etc.

What types of Isolators are there?

There are two main types of Isolators: Positive pressure isolators (protecting the product); Negative pressure isolators (protecting the operator and the external environment).

Why is it necessary to use Isolators?

In addition to basic features like interlocking doors and UV lights, a Dynamic Pass Box also generates clean air through a fan and HEPA filter, cleaning items during transport.

Why is it necessary to use Isolators?

Isolators provide complete separation between the process and the surrounding environment, helping to protect the product from contamination and safeguarding both personnel and the external environmen

What are the standards for Isolators in the pharmaceutical industry?

Pharmaceutical isolators need to comply with Class A standards according to EU GMP classification (as outlined in the EU GMP Classification OJ 07/01/97 document).

What are the applications of pharmaceutical Isolators?

Handling, filling various pharmaceutical dosage forms such as solid, semi-solid, or powder, solutions, and infusions; Aseptic testing, coarse filtration, drying, and weighing of cell toxicants, ...